Silicon Valley growth has gained significantly in the development of software, web and other digital mediums. What has happened to 3 dimensional products that people touch? Well locally, much of it has diminished or moved to other areas of the world.

Long ago,at the beginnings of StudioRed, when I first came to Silicon Valley in 1981, we designed many computers. Remember Osborne, Grid Systems, Morrow Computers, DEC, Televideo, AMD, Fujitsu, Samsung even Zenith? The list is quite long and only a few are noted herein; however, as time passed, we saw this market evolve and shrink.

Later, in the 90’s, networking and technology giants like 3Com, Adaptec, Cisco, Juniper, AT&T, Motorola, Nokia, Palm, Handspring, Ricoh, began branding their devices; they all did their industrial design and mechanical engineering with local talent. The resulting products and programs were appropriate, innovative, and in many cases- market makers. Some were “me-too” products, but often it was only the Silicon Valley designers that brought the experience necessary to conquer these unique product development challenges.

Then came the increased medical device development: Abbott, Arthrocare, Becton Dickinson, Boston Scientific, Coherent Laser, Laserscope, and Resound, which allowed us to bring the advanced technology to market-ready product offerings. Along with natural product design challenges of the functional operation, ergonomics, and safety, this work included design research of patients, doctors and their offices, emergency and surgical rooms and nurse and technician practices. Mockups for worldwide focus groups, iterative studies, prototyping and lots of creative design work occurred often and engaged everyone- designers, engineers and model builders.

As the innovation capital of the world, Silicon Valley still encompasses the greatest innovators in many industries. Product development is still alive and well with new categories of R&D encompassing real, tangible things people touch, feel, interact with and love to own. I think the strongest area is in biotech and medical devices slightly ahead of systems which collect, aggregate and present data collected in the millions of already-placed sensors within our lives.

Advances in DNA, molecule, and disease testing are at an all-time high. On top of that, surgical, vascular and heart focused productscontinue to grow in new product development. Inductive charging has created new unique products to solve previously wired battery charging challenges. Consumer products that combine the integration of tangible products with web based analytics to give users new information about their home, family, kids and or car is super active and growing. This is an interesting variant on the Internet of things (IOT) that will be strong for years to come.

Where some industries were initially driven by form-follows-function, such as production equipment, manufacturing machinery or military defense products, now many are trying to separate themselves from the pack by advancing product design and branding ahead of functionality alone. Function cannot be compromised, but if a product is memorable and represents the brand in a more compelling way; the company is more notable and gains an audience where others will not.

Recently there is a push to create fresh design innovations forcompanies which originally drove design from the inside out, meaning components and function are defined first, then the product is designed around them.Now they are asking for creative design studies focusing on new product style and form, which later will require them to figure out how to make the components fit. This can often lead to real product innovation and out-of-the-box thinking in both the human interaction and overall style.

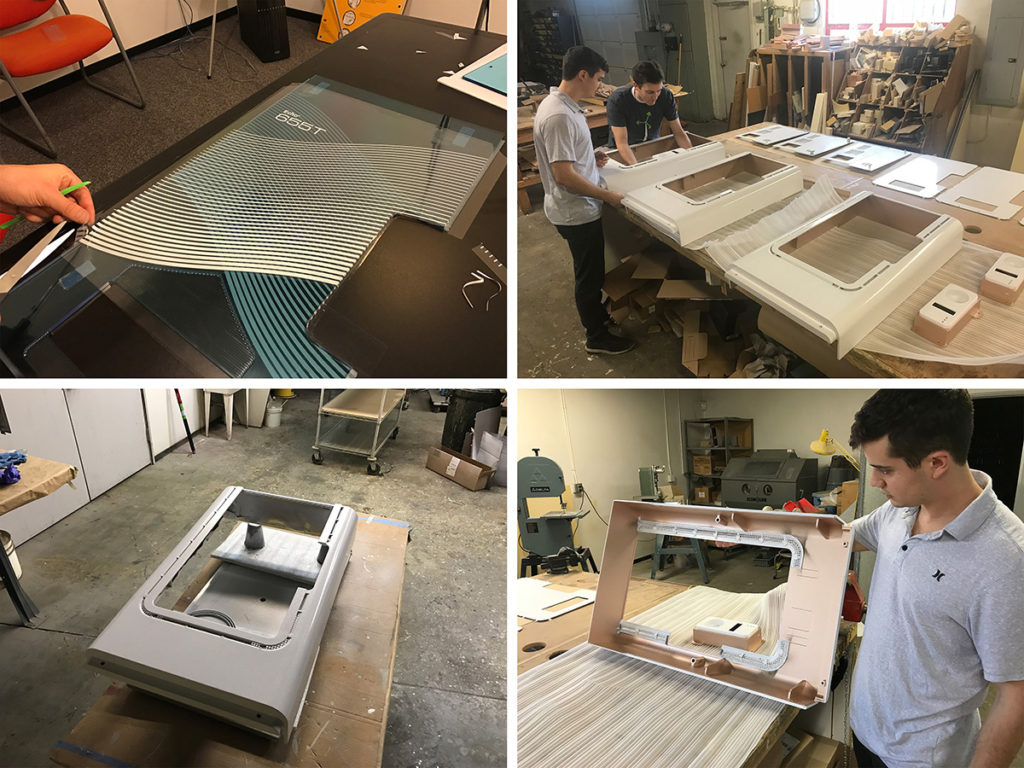

Secondary markets such as prototyping, machining, casting and painting are still active although significantly reduced from 10 or 15 years ago when hardware development here in the bay area was much stronger. The specialty areas of high tolerance Computer Numeric Control machining, material characteristics testing and iterative prototype development are still necessary steps in the R&D process but the total market size is reduced and only specialized firms are still active and financially healthy enough to pursue this in the Silicon Valley.

We hope these market areas expand and evolve even further in the future so we can keep our industrial designers, mechanical engineers and machinists and model builders happily engaged in the future of products for us all. – Philip Bourgeois